Manifattura Bulgari: the largest jewelry production plant in Europe

A young quarry of artisans puts into operation every day the largest jewelery production plant in Europe, the Bulgari Manifattura. We visit this complex that the Italian house has built in Valenza, a town that in the 19th century was the epicenter of goldsmithing on the continent.

Victoria ZarateAt the beginning of the 19th century, the master Francesco Caramora had a hunch. Trained in the art of goldsmithing, which since ancient times had been carried out in Voghera, in his native Pavia, he decided to head to Valenza, a farming town in the Alessandria region, in northern Italy. There he would establish his production workshop, from which he would pass on the noble craft of metal to future disciples. Thus, the foundations were laid for what would soon be considered the epicenter of goldsmithing in Europe. Today, the district of Valenza encompasses eight municipalities specialized in the production of high-end jewelery and goldsmith pieces, the region with the highest density of goldsmiths in Italy and companies linked to Made in Italy brilliance that defend the slow and meticulous work of their artisans in the face of hectic industrial production times. On the outskirts of the city, the sign of one of the factories stands out above the rest. They are the golden letters that announce the entrance to the Manifattura Bulgari, the epitome of Italian luxury since its creation in 1884. “We wanted the memory of Bulgari's aesthetic to be present from a contemporary point of view. It is a unique manufacture that conveys the essence of the Bulgari universe, between the legacy and the future”, explains Mauro di Roberto, director of the firm's jewelry area, minutes before the visit to its facilities.

With a total area of 15,000 square meters, the heritage of Caramora is palpable in every corner of this production plant inaugurated in 2017. Its design, by the Open Project architecture studio, is made up of two buildings with well-differentiated and connected styles each. The most voluminous complex, a new construction, houses the production rooms under a metal skin free of visual barriers to nature. It consists of three floors distributed around an interior patio of about 600 square meters, an architectural challenge that guarantees natural light in each workstation. The second building, completely restored and expanded with a new glass-clad wing, is a symbol of the city. This is the Cascina dell'Orefice, the farm that Caramora acquired in 1860 as a residence and workplace, and which enjoyed international fame. There are even references to his workshop on Napoleonic maps. “This is a historic place. The first jewelry production was made here, so it seemed extremely valuable to us to plan the plant in this place”, says Mauro di Roberto. Caramora's fame and work, which turned Valenza into the gold capital of the world, did not exempt him from debt. The farmhouse was put up for sale after his death. It was bought by one of his assistants, Piero Canti. Two centuries later, already in the hands of the Bulgari empire and as an emblem of the LVMH group to which the Italian firm belongs, that same energy that Caramora transmitted to his students is still alive in the bowels of the largest jewelry manufacturer in Europe.

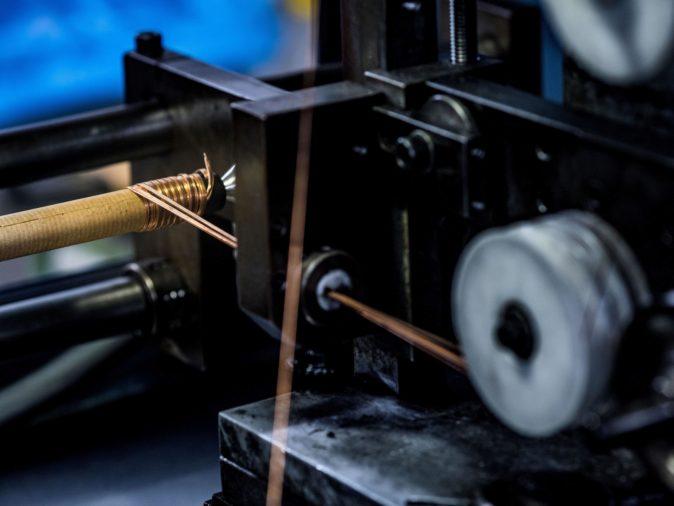

After leaving the historic area, destined for offices and meeting rooms and armed with elements common to its stores around the world (the geometric latticework, Italian marble and oak wood or the eight-pointed star), one enters the production facilities, a craft laboratory that moves freely between past and future whose starting point is found in the modeling rooms. Here, ancestral techniques such as wax molding, used for small pieces with little formal complexity, are mixed with 3D printing, intended for the most complex parts. Next come the 18 islands that comprise the production plant. Martina, 32, is in charge of one of them. Sheathed in leopard sneakers and horn-rimmed glasses, this mechanical engineer landed in the factory five years ago. “Here we all learn to do everything”, she announces, referring to each of the phases of the process by which the piece of gold removed from the mold is transformed into a goldsmith's jewel. From the assembly to the engraving of the famous made in Italy, through the inlay of diamonds and precious stones or the soaping. Her methodology follows the traditional steps established by goldsmiths like Caramora, but supervised by digital screens.

Youth is a common denominator in almost all departments. “Many of our artisans are from abroad, especially from southern Italy. Since we opened in 2017 we have doubled the number of operators, from 350 to the current 700, and a large part of the workforce is young people, a good indicator for us, since it guarantees us a future. These girls and boys bring a lot of energy, something very valuable also for the city”, says Mauro di Roberto. Perpetuating this noble profession among the new generations is one of the company's objectives and a fundamental value of the Bulgari Academy. Each year this technical school receives new students from different universities to instruct them in the different techniques that make up goldsmithing. “The market is booming and everyone is looking for goldsmiths. Today our great handicap is to find young people who want to perform and learn the springs of this trade”, explains Di Roberto.

Valuing the space in which its artisans work made the construction of the building itself subject to an ambitious sustainability plan that received the international Gold LEED (Leadership in Energy & Environmental Design) certificate, which is awarded to projects with low environmental impact in their planning. “The space maximizes the use of natural light together with the LED lighting of the facilities. Use only electricity from renewable sources. It also uses irrigation systems that allow water to be reused, reducing its consumption by up to 42%”, details Eleonora Rizzuto, director of corporate social responsibility at Bulgari.

The number of pieces that come out of their workshops takes a backseat to the hours that each craftsman spends in the different production phases. "It is what really adds value to the jewel," says Di Roberto. The hands of its artisans work some of the most precious pieces of the Italian firm, such as the faceted spirals that pay homage to the Colosseum in Rome in the B.zero1 line or the characteristic articulated cord of the Serpenti pieces, the most laborious in the catalog of the Mark. Sculpted in white gold and recognizable by the two emeralds that shape the reptile's eyes, some of them have up to 82 hand-encrusted diamonds. According to Martina, this task involves the work of three people for a whole week. A meticulous job that she is very proud of: "I used to work in the food sector, but this is much more interesting, you know what jewelry means to a girl." The craftsmanship carried out by this young quarry of artisans in Valenza is added to the Bulgari high jewelry laboratory in Rome, the accessories factory in Florence and the watchmaking workshops owned by the brand in Switzerland. One more chapter of that well-matched marriage that the Italian firm has established with the crafts of its country throughout its history and that, like the diamonds that its artisans embellish every day, for the moment seems unbreakable.

Rules

![47 best antiage nutritive cream in 2022 [based on 326 reviews] 47 best antiage nutritive cream in 2022 [based on 326 reviews]](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_6/2022/2/27/1918fc37c66ad30564173e69d9df88a0.jpeg)